The Oil & Gas Strategy drives the focus on Operational Excellence: Operational Efficiency, Cost reduction and Continuous improvement

In today’s business environment, achieving Operational Excellence is a goal for any company striving for success.

“The energy industry remains under heavy financial pressure. Strategy drives a focus on operational excellence (e.g., Efficiency, Reliability and cost reduction). The slowdown of retail market restructuring requires reassembling previously disintegrated retail and distribution lines of business. To achieve operational excellence, companies must optimize integrated business processes

Driven by the increased focus on operational efficiency in 2003/04, energy companies will increase spending on analytic architectures and business intelligence solutions (e.g., ETL*, LOBs** operational data stores, KPI executive dashboards/portals). In addition to supporting the LOB** quest for excellence in the short term, during 2005-07 this will lead to energy companies transformation into real-time enterprises, enabling increased agility and improved visibility (by regulators and customers alike), ultimately ensuring better value creation from existing IT investments.”

"The Operational Excellence Challenge Trend Teleconference" Terry Ray

*ETL: Acronym for database operations of Extract, Transfer, and Load

**LOB: Line Of Business

Any process in life can be mapped. Then, its performance can be optimized.

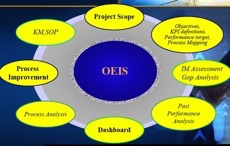

Operational Excellence Information System is a tool designed to achieve continous process monitoring and optimization. The implementation of OEIS is based on the 6-sigma DMAIC concept. It targets performance monitoring and continuous improvement.

The objective:

- Monitor the performance of a process

- Identify major cause of failure and major areas of improvement

- Act on them efficiently

- Allows continuous improvement and prevents failure reoccurrence

- Updating the Standard Operating Procedures

- Capture knowledge, lessons learnt and local best practices

The Benefits:

- Maximizing efficiency

- Improving quality

- Lowering total cost of ownership (TCO)

- Boosting reliability and availability

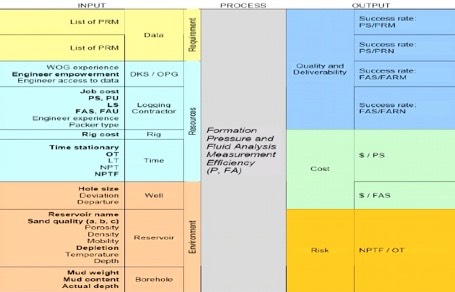

Example: Wireline Formation pressure data acquisition

Process description:

Wireline Logging targets to deliver optimum quality data, as per Client requirements specified on the logging programs, in a cost efficient and low risk manner

Identified Business Drivers and associated KPI:

- Data Quality and deliverability (fit to the request)

- % PS/PRM (pressure successfully recorded / pressure requested good reservoirs)

- % PS/PRN (pressure successfully recorded / pressure requested poor reservoirs)

- Total Cost

- $/PS (total cost (direct and indirect) of a successful pressure test)

- Risk

- % NPTF/OT (Non Productive Time due to Fishing / Operating Time)

IPO diagram (input-process-output):